Product

Information

Tubular Conveyor

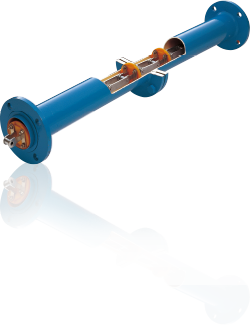

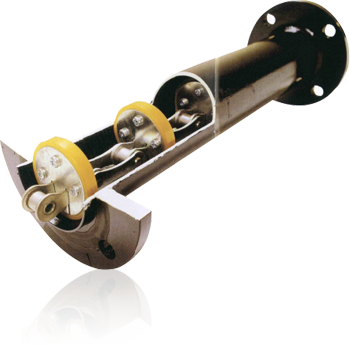

The Tubular Conveyor safely and cleanly transports powders, granular materials, and muddy materials and consists of a pipe casing and flights (disk-shaped plates) moved by a conveyor chain inside the casing.

Versatile transport style

The conveyor can be completely sealed to keep out the outside air. Multi-supply and discharge ports can be installed on the conveyor, making it suitable for various applications.

Compact and free layout is possible.

The use of the pipe casing allows ease of installation in crowded areas with simple support and allows layout in any direction: horizontal, vertical, or inclined.

Tubular Conveyor Introduction Video

Roles of Tubular Conveyor

Flexible layouts according to the installation conditions!

The Tubular Conveyor provides efficient and clean powder and granular conveying, enhancing plant system safety and environmental protection.

Safe and clean transportation.

The Tubular Conveyor safely and cleanly transports powders, granules, muddy chemicals, and other materials that must not be scattered in the surrounding environment.

Shutting off transported items

from the outside air.

The Tubular Conveyor is completely sealed to prevent dust, odor, dirt, etc., from leaking outside.

It can also seal and transport hazardous materials and specific gases that are dangerous when exposed to the atmosphere.

Protecting the environment

inside industrial plants.

The Tubular Conveyor is economical, has low maintenance costs, and enhances plant system safety and environmental protection.

PVC powder, PVC stabilizer, PE powder, ABS powder, PTA powder, lead powder, pulverized coal, carbon black, iron oxide, lead oxide, cement, limestone powder, quicklime, slaked lime, magnesium hydroxide, calcium carbonate, magnesium carbonate, chlorine dust, and tar sludge

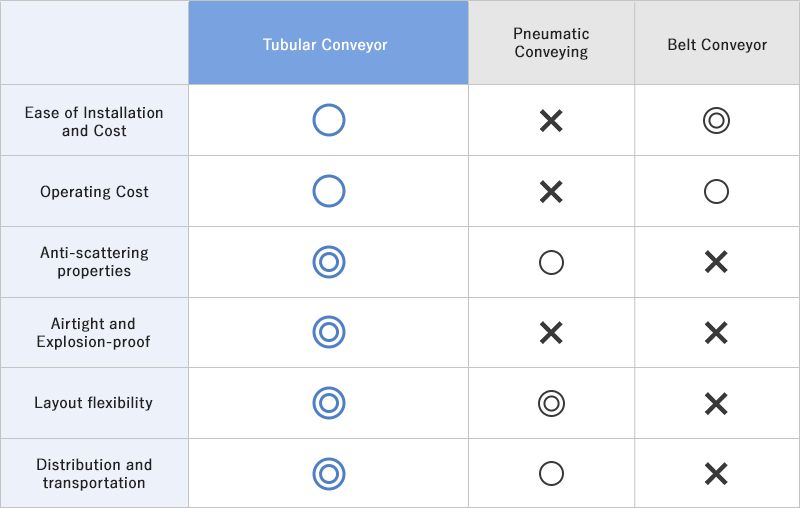

Features and Advantages of Tubular Conveyor

- Conveys objects horizontally, vertically, or at an incline and can be freely laid out.

- Compact and easy to install using a pipe casing in a limited space.

- Completely sealed to prevent leakage of dust, odors, and contaminants.

Hazardous materials that may come into contact with the atmosphere are sealed with specified gases for transportation. - Multiple inlets and outlets can be easily installed in the middle of a conveyor line, enabling distribution conveying without complicated switching control.

- A large amount of compressed air is not required, reducing running costs.

- Lower maintenance costs and more economical than pneumatic conveying.

Comparison with other conveyors and types of tubular conveyors

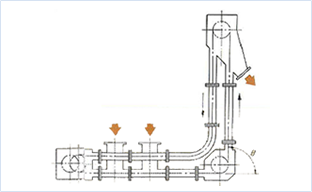

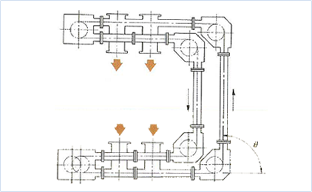

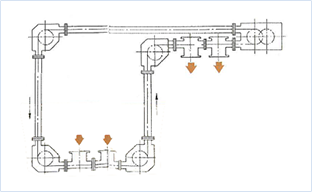

LModel

The material is transported horizontally or at an incline. Multiple inlet and outlet ports can be installed.

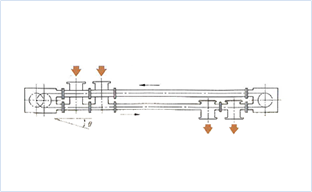

PLModel

The material is transported horizontally or inclined. Multiple inlet and outlet ports can be installed.

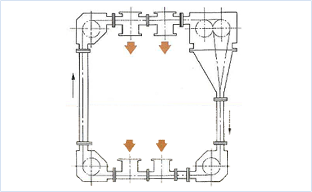

SQModel

The material to be transported is fed into the lower horizontal section, transported vertically, and discharged at the upper horizontal section. Multiple inlet and outlet ports can be installed.

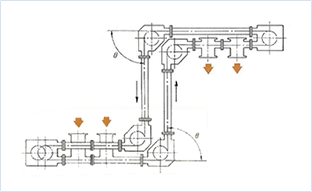

ZModel

The material to be transported is fed into the lower horizontal section, transported vertically, and discharged at the upper horizontal section. Multiple inlet and outlet ports can be installed.

CModel

The material to be transported is fed into the lower horizontal section, transported vertically, and discharged at the upper horizontal section. Multiple inlet and outlet ports can be installed.

GNModel

The material to be transported is fed into the lower horizontal section, transported vertically, and discharged at the upper horizontal section. Multiple inlet and outlet ports can be installed.

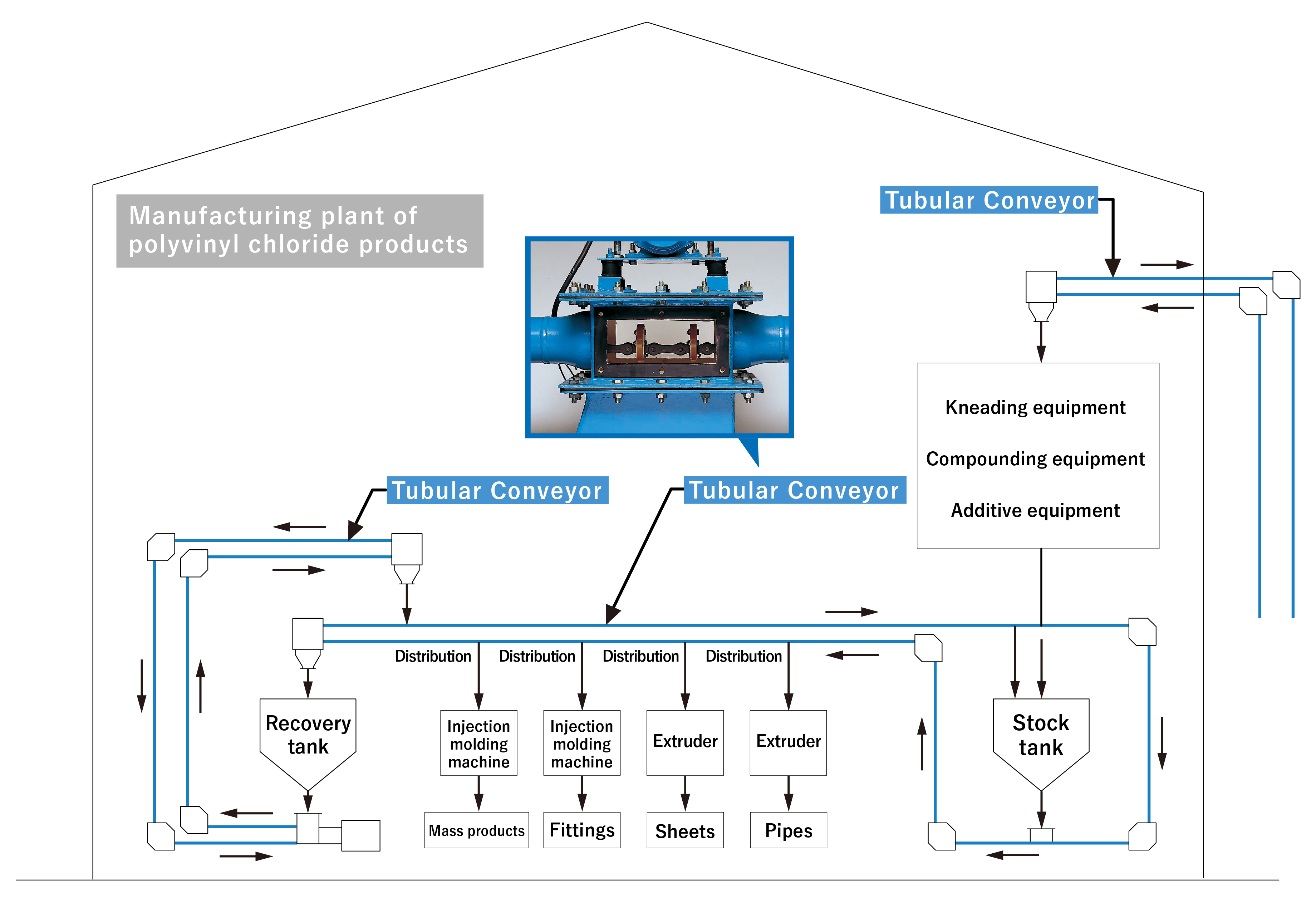

Case example: Polyvinyl chloride product facilities

Vinyl chloride resin is one of the plastics we use daily, and it is used in products all around us. These products include signboards, stationery, clothing, vehicles, wallpaper, decorative film, floor sheets, floor tiles, furniture, sofas, chairs, and car seats. In the manufacturing process of vinyl chloride products, the Tubular Conveyor is used to transport raw materials safely.